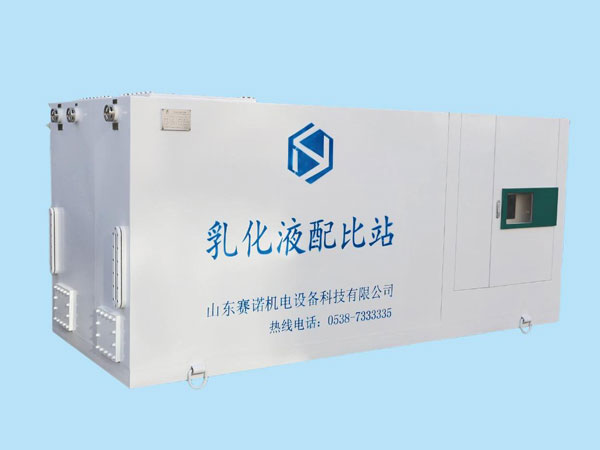

1、Purpose:The fully automatic underground emulsion mixing station is suitable for automatic mixing of emulsions in coal mine un.derground working faces. lt can achieve real-time monitoring of concentration, automatic control of mixing and adjustmentof mixing concentration, automatic replenishment, and real-time monitoring and data display of key parameters; At the sametime, prepare emulsion that meets the usage requirements according to the needs of the working face, providing a stable ancreliable working medium for the hydraulic system of the support.

2、Technical parameters

(1)Model:KRPYZ-10

(2)Rated liquid dispensing capacity: 10m3/h

(3)Solution concentration range: 1%~7%.

(4)Equipment power supply: 660/1140 VAC.

(5) linterface: DN50 quick plug at the inlet; The DN25 hose at the oil pump suction port is directly put into the commercial

emulsified oil drum.(6) Discharge method: DN50 quick plug hose is directly sent into the emulsion tank of the mining party, with a conveyingpressure of not less than 0.5MPa.

(7) Capacity: The water tank should not exceed 2000L; Emulsified fuel tank > 600L; Emulsion tank > 700L (expand.

able to fuel tank).

(8) Real time upload of operational data, with RS485 signal upload.(9)Equipment dimensions: not exceeding 3000 (length)*1250 (width)* 1450 (height) mm

3、Main features:

11) Bealize automatic online detection of water tank level oil tank level liauid tank level and emulsion concentrationand display them in real-time on the controller screen.

(2) Realize automatic control of water level in the water tank, with low-level replenishment and high-level automaticstop of water intake, Water tank low level alarm, stop dispensing at extreme low level.

(3) Electric control oil pump refueling, automatic pump stop when the fuel tank is ful; Fuel tank low level alarm, stop dispensing at extreme low level.(4) Low level automatic dispensing of emulsion tank, high level automatic stopping of dispensing; The concentratiorof the solution can be adjusted in real-time online; High stability mixing device, strong mixing and emulsification.(5) There is an emulsified oil filter with a required accuracy of not less than 80 y m, and the filter element can be dis-assembled and cleaned for repeated use.

(6) The equipment should have functions such as displaying operating status and alarms.

(7) The equipment should have human-machine dialogue function, which can achieve online parameter settingthrough menu operation, realize timely adjustment of equipment operating parameters, and have automatic and manualcontrol modes.

(8)The equipment is equipped with stabilizing and defoaming devices.

(9) Pre set the overall connection control function with the mining liquid tank.

(10) All components in contact with liquids aremade of stainless steel material; All boxes and fittingsare made of stainless steel material, and the thicknesSof the stainless steel plate is not less than 4mm.

(11)The product is suitable for underground workingconditions in coal mines and is resistant to impact andcollision: Heavy duty desian for all fittings and pipelines